The world of seals and service

Welcome to the online version of our popular print magazine.

On this site, you'll find articles from the current and previous issues, including interviews with leading industry experts, in-depth application case studies and the latest news on sealing technology and industry trends.

On this site, you'll find articles from the current and previous issues, including interviews with leading industry experts, in-depth application case studies and the latest news on sealing technology and industry trends.

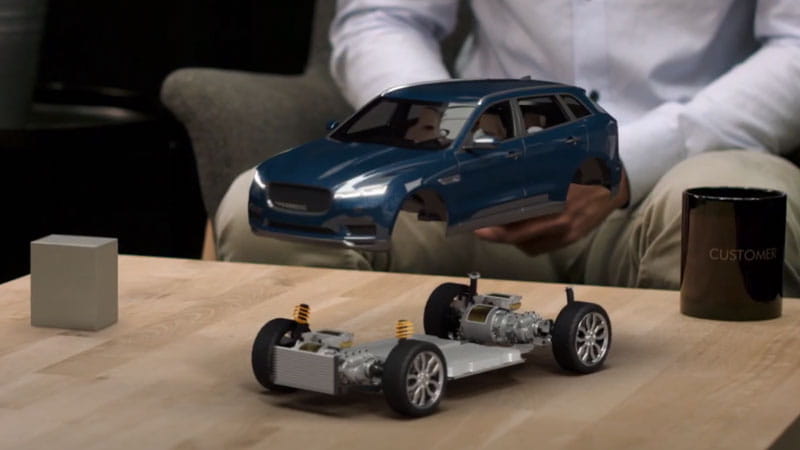

In the Groove Goes Digital

In the groove, the Trelleborg Sealing Solutions customer magazine, is now an interactive reading experience! The digital version of our magazine provides a seamless viewing experience by enabling engagement with the content via various interactive features. These make our magazine easy to consume and even more interesting for the reader, all made possible thanks to the iPaper online platform. The same functionality is used by Trelleborg’s T-Time magazine.

iPaper Demo

Interested in seals and silicone solutions?

Learn more about what we can do for you: